Process

The vineyards are exhaustively monitored each year to ensure that the grapes that arrive at the winery are of the highest quality.

Walk through the whole process

The land and the vine are fertilized exclusively with organic fertilizers. This achieves a production of less than two kilos per vine; a limited production in which all of the soil’s minerals and nutrients are concentrated.

The Vineyard

We also refrain from using herbicides or any other aggressive treatments on the vineyards.

Manual harvest

Applying the same strict criteria, the grapes are selectively hand-picked. We visit all the plots everyday where we take berry samples, taste and analyze them. The grapes are harvested in terms of their ripeness.

If the moment is optimum and the grapes have a potential alcohol content over 11ª, they are hand-picked, placed in 12 kg boxes and led to the winery.

Selection

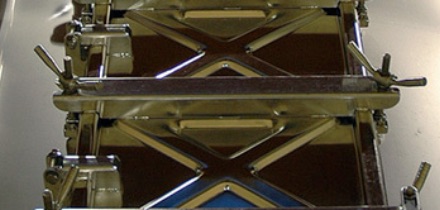

When the grapes arrive at the winery, the contents of each box are placed on a sorting table where qualified personnel carries out a more exhaustive selection.

The clusters are then destemmed and the grapes are gently taken in special containers to the fermenter that has been previously assigned to them. This ensures that each tank contains similar grapes to be used in making each type of wine.

Fermentation

Once the grapes have been placed in the fermenters, they are subjected to cold maceration at temperatures under 15 °C for three days.

Then, alcoholic fermentation begins. It usually lasts about 10 days and occurs at controlled temperatures under 30 °C.

After fermentation, the wine is left to macerate at a constant temperature of 25 °C for 8 to 10 days, depending on the result of repeated tastings.

Later, between the second half of November and the first half of December, the wine spontaneously undergoes malolactic fermentation at a temperature of about 22 °C for approximately 15 days. The wine is left in vats where it is naturally fined.

Ageing in barrel

The wine’s ageing begins in new casks made with French, American and Central Europe oak, always fine grain.

The ageing process takes from 5 to 24 months in underground spaces that have been designed to automatically control ventilation, humidity and a constant temperature of 15-16 °C.

The wine is racked and the casks are refilled with wine of the same quality every 6 months, to achieve better natural fining.

Bottling

The wines are bottled using a continuous, gravity-fed system that avoids the sudden starts and stops of other bottling methods since they can damage the wine.

The stoppers are made of top-quality cork “the best known closure method known to date” and subjected to strict quality controls and tests.

Ageing in Bottle

Bottle ageing requires time and painstaking control.

The wines of Abadía de Acón age in bottles in specially air-conditioned areas. External equipment ensures that the bottle ageing hall remains at a constant temperature. Here the bottles rest between 14 and 20 months.

Silence, darkness and an unhurried approach will take us back in time.